Filament Spectrum Nylon PA6 Low Warp CF15S 1.75mm BK 0.50kg

Filament Spectrum PA6 Low Warp CF15S

Low shrinkage and high strength paired up with the advantages of carbon fibres

Polyamide 6 is one of the strongest materials used in desktop 3D printing technology. It combines mechanical strength,...

Filament Spectrum Nylon PA6 Low Warp CF15S 1.75mm BK 0.50kg

Spectrum color name: Black

Choose another$36.99 USD

Description

Filament Spectrum PA6 Low Warp CF15S

Low shrinkage and high strength paired up with the advantages of carbon fibres

Polyamide 6 is one of the strongest materials used in desktop 3D printing technology. It combines mechanical strength, stiffness, vibration damping ability and abrasion resistance unmatched by any other types of filaments. It can successfully add chemical resistance and the ability to operate continuously at high temperatures to its wide range of properties.

With the introduction of heat-stabilised, carbon fibre-filled Spectrum PA6 Low Warp CF15S composite material, we set out to raise the bar for nylon filaments even higher. Spectrum PA6 Low Warp CF15S is a true heavy-duty specialist. The "LowWarp" moel is characterised by extra mixture content designed to improve the flow during extrusion of the material - and thus improved adhesion of the material particles. With the use of 15% carbon fibres, the stiffness goes up over two times and tensile strength improves (up to 120 MPa). In addition, Spectrum PA6 Low Warp CF15S has a higher HDT thermal resistance of 180°C (0.45MPa), compared to the unfilled version. The fibre content reduces the shrinkage, which is common or most high-temperature materials, making the printing process much easier and giving prints an aesthetically pleasing "carbon-like" look.

Spectrum PA6 Low Warp CF15S is the best choice for printing functional models that require high rigidity and continuous high-temperature and chemical resistance. It can easily be used in the automotive, aerospace and modelling industries.

Key features:

- 15% carbon fibres

- two-fold increase in rigidness compared to non-modified polyamid

- high mechanical properties and abrasion resistance

- excellent chemical resistance

- HDT thermal resistance - 180°C (0.45MPa)

- printable on desktop devices without a heated chamber

- matt, carbonised print surface

- perfect bonding of the layers

Applications:

- functional prototype,

- production tooling

- working components of tools and machinery - rotors, gears

- guides, gear racks, guide rollers

- manufaturing protective rings and plates with increased chemical and corrosion resistance

Packaging

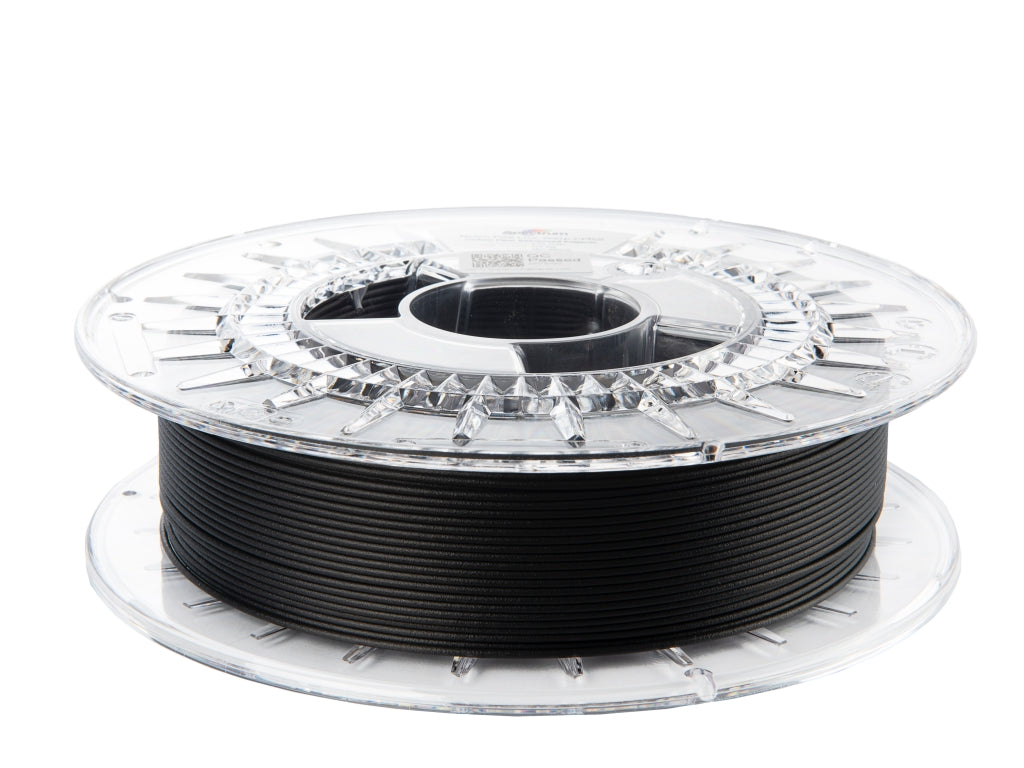

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

250

44

140

52

120

Plastic

Transparent

250

44

140

52

80

Cardboard

-

500

55

200

52

240

Plastic

Transparent

750

55

200

52

240

Plastic

Transparent

1000

67

200

52

260

Plastic

Transparent

1000

67

200

52

180

Cardboard

-

2000

100

300

52

600

Plastic

Black

2000

100

300

52

420

Cardboard

-

4500

100

350

52

780

Plastic

Black

8000

167

355

36

1020

Plastic

Black

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Description

Filament Spectrum PA6 Low Warp CF15S

Low shrinkage and high strength paired up with the advantages of carbon fibres

Polyamide 6 is one of the strongest materials used in desktop 3D printing technology. It combines mechanical strength, stiffness, vibration damping ability and abrasion resistance unmatched by any other types of filaments. It can successfully add chemical resistance and the ability to operate continuously at high temperatures to its wide range of properties.

With the introduction of heat-stabilised, carbon fibre-filled Spectrum PA6 Low Warp CF15S composite material, we set out to raise the bar for nylon filaments even higher. Spectrum PA6 Low Warp CF15S is a true heavy-duty specialist. The "LowWarp" moel is characterised by extra mixture content designed to improve the flow during extrusion of the material - and thus improved adhesion of the material particles. With the use of 15% carbon fibres, the stiffness goes up over two times and tensile strength improves (up to 120 MPa). In addition, Spectrum PA6 Low Warp CF15S has a higher HDT thermal resistance of 180°C (0.45MPa), compared to the unfilled version. The fibre content reduces the shrinkage, which is common or most high-temperature materials, making the printing process much easier and giving prints an aesthetically pleasing "carbon-like" look.

Spectrum PA6 Low Warp CF15S is the best choice for printing functional models that require high rigidity and continuous high-temperature and chemical resistance. It can easily be used in the automotive, aerospace and modelling industries.

Key features:

- 15% carbon fibres

- two-fold increase in rigidness compared to non-modified polyamid

- high mechanical properties and abrasion resistance

- excellent chemical resistance

- HDT thermal resistance - 180°C (0.45MPa)

- printable on desktop devices without a heated chamber

- matt, carbonised print surface

- perfect bonding of the layers

Applications:

- functional prototype,

- production tooling

- working components of tools and machinery - rotors, gears

- guides, gear racks, guide rollers

- manufaturing protective rings and plates with increased chemical and corrosion resistance

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

| Content [g] | Width [mm] | Outer diameter [mm] | Inner diameter [mm] | Weight empty [g] | Material | Spool color |

|---|---|---|---|---|---|---|

| 250 | 44 | 140 | 52 | 120 | Plastic | Transparent |

| 250 | 44 | 140 | 52 | 80 | Cardboard | - |

| 500 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 750 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 260 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 180 | Cardboard | - |

| 2000 | 100 | 300 | 52 | 600 | Plastic | Black |

| 2000 | 100 | 300 | 52 | 420 | Cardboard | - |

| 4500 | 100 | 350 | 52 | 780 | Plastic | Black |

| 8000 | 167 | 355 | 36 | 1020 | Plastic | Black |

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Do you need help? Do you have any questions?

Ask a question and we'll respond promptly, publishing the most interesting questions and answers for others.

High quality filaments

Wide portfolio consisting of over 80 filaments with a versatile range of properties and applications, divided into three segments: desktop easy-to-use, industrial grade and high performance.

European manufacturing

All filaments from our portfolio are in-house made. We use modern production lines equipped with non-standard solutions to obtain highest quality final product.

technical support

Our qualified support team helps at every stage from material selection to the 3D printing process.