Filament Spectrum S-Flex 98A 1.75mm GLOW IN THE DARK 0.5kg

Filament Spectrum S-Flex 98A

Flexibility with very good impact strength and thermal insulation

Spectrum S-Flex 98A is a filament based on a thermoplastic polyether polyurethane. In the area of additive manufacturing, S-Flex 98A is a material characterized by a relatively...

Filament Spectrum S-Flex 98A 1.75mm GLOW IN THE DARK 0.5kg

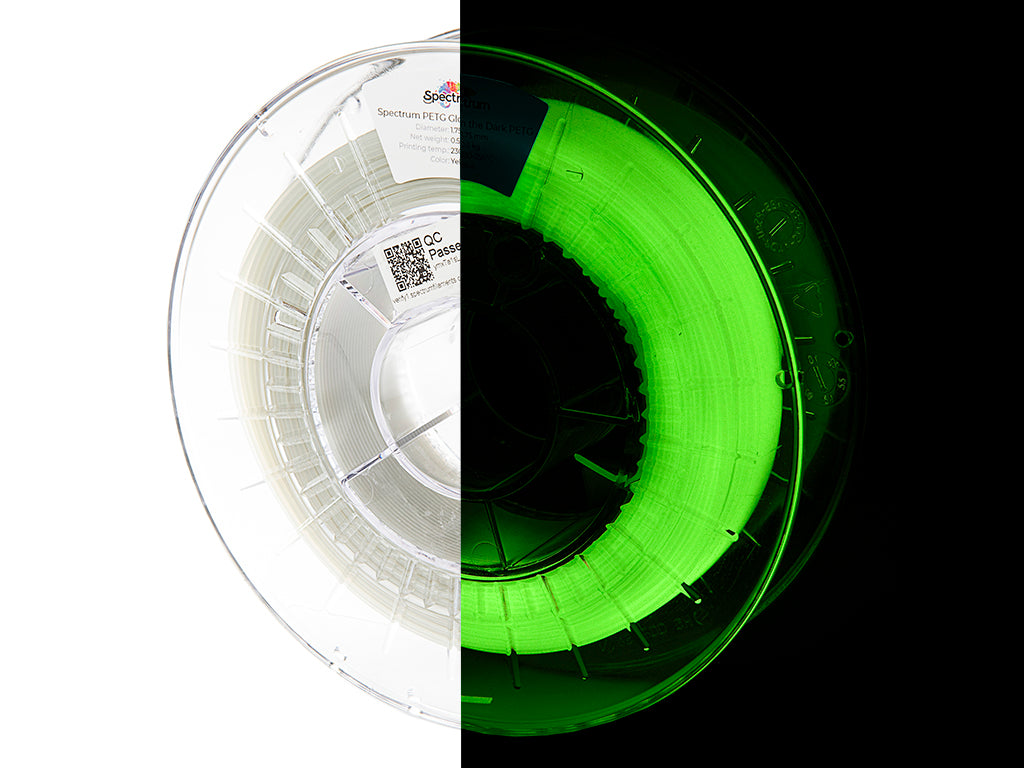

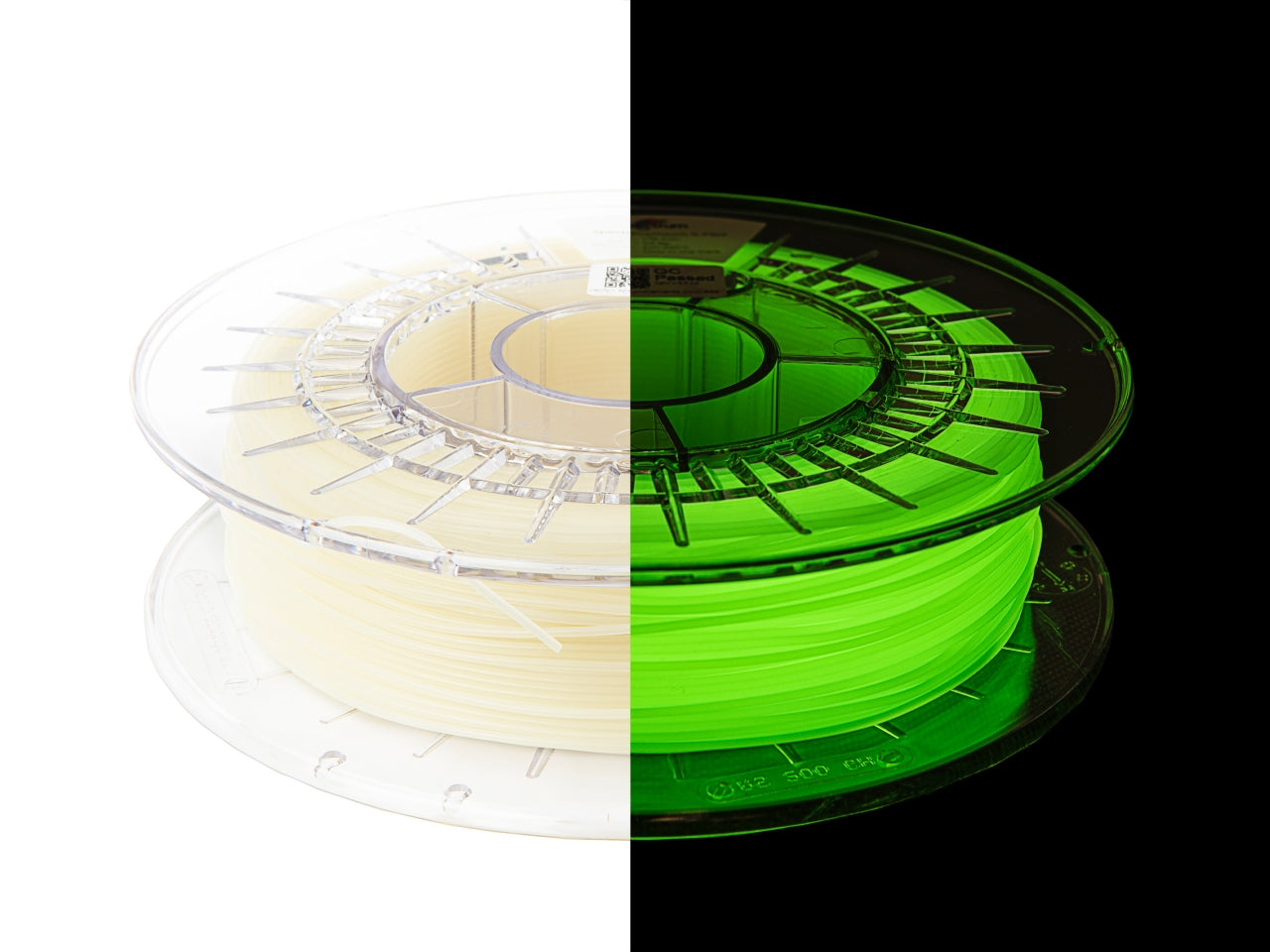

Spectrum color name: Green/Natural

$57.99 USD

Description

Filament Spectrum S-Flex 98A

Flexibility with very good impact strength and thermal insulation

Spectrum S-Flex 98A is a filament based on a thermoplastic polyether polyurethane. In the area of additive manufacturing, S-Flex 98A is a material characterized by a relatively easy and failure-free 3D printing process. An additional advantage that allows obtaining a perfect printout is very good adhesion of the first layer of the printed part to the working space, regardless of whether it is made of glass, steel, plastic or other material.

Low processing shrinkage and high flexibility significantly reduce the risk of the so-called curling up of the edges of manufactured parts. The distinguishing feature in the filament name - 98A – relates to the hardness of the material on the Shore scale and classifies Spectrum S-Flex 98A in the category of hard elastomers. This property - from the point of view of the 3D printing process - reduces the risk of filament deformation in the insertion system leading the material to the printing head. This enables a slightly faster printing compared to other, more compliant elastomers.

Parts made of Spectrum S-Flex 98A are characterized by very high resistance to hydrolysis (a kind of degradation caused by the presence of water), good recyclability and very good resistance to dynamic forces. Thanks to these properties, it is possible to 3D print parts that protect surfaces exposed to impact (bumpers, sharp edge guards), sealing and protective elements with high chemical resistance, as well as thermal insulators.

Key features:

- high resistance to hydrolysis

- up to 510% elongation at break

- Shore-A hardness of 98

- high tensile and tear resistance

- low shrinkage

- resistance to many common industrial oils and chemicals

- reduced stringing while the printer is running idle

Applications:

- manufacturing of seals with a high chemical resistance

- production of items, which has to be used as energy adsorbents

- functional parts

- all kinds of bumpers, vibration dampers

- guides

- protective cases

- snap-fit parts

- sleeves

- hinges

- bumpers and flexible spacers,

- sealing parts with increased stiffness,

- spring-damping elements for use in machine production and modeling,

- flexible bands with high strength,

- covers and housings for various devices,

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

250

44

140

52

120

Plastic

Transparent

250

44

140

52

80

Cardboard

-

500

55

200

52

240

Plastic

Transparent

750

55

200

52

240

Plastic

Transparent

1000

67

200

52

260

Plastic

Transparent

1000

67

200

52

180

Cardboard

-

2000

100

300

52

600

Plastic

Black

2000

100

300

52

420

Cardboard

-

4500

100

350

52

780

Plastic

Black

8000

167

355

36

1020

Plastic

Black

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Description

Filament Spectrum S-Flex 98A

Flexibility with very good impact strength and thermal insulation

Spectrum S-Flex 98A is a filament based on a thermoplastic polyether polyurethane. In the area of additive manufacturing, S-Flex 98A is a material characterized by a relatively easy and failure-free 3D printing process. An additional advantage that allows obtaining a perfect printout is very good adhesion of the first layer of the printed part to the working space, regardless of whether it is made of glass, steel, plastic or other material.

Low processing shrinkage and high flexibility significantly reduce the risk of the so-called curling up of the edges of manufactured parts. The distinguishing feature in the filament name - 98A – relates to the hardness of the material on the Shore scale and classifies Spectrum S-Flex 98A in the category of hard elastomers. This property - from the point of view of the 3D printing process - reduces the risk of filament deformation in the insertion system leading the material to the printing head. This enables a slightly faster printing compared to other, more compliant elastomers.

Parts made of Spectrum S-Flex 98A are characterized by very high resistance to hydrolysis (a kind of degradation caused by the presence of water), good recyclability and very good resistance to dynamic forces. Thanks to these properties, it is possible to 3D print parts that protect surfaces exposed to impact (bumpers, sharp edge guards), sealing and protective elements with high chemical resistance, as well as thermal insulators.

Key features:

- high resistance to hydrolysis

- up to 510% elongation at break

- Shore-A hardness of 98

- high tensile and tear resistance

- low shrinkage

- resistance to many common industrial oils and chemicals

- reduced stringing while the printer is running idle

Applications:

- manufacturing of seals with a high chemical resistance

- production of items, which has to be used as energy adsorbents

- functional parts

- all kinds of bumpers, vibration dampers

- guides

- protective cases

- snap-fit parts

- sleeves

- hinges

- bumpers and flexible spacers,

- sealing parts with increased stiffness,

- spring-damping elements for use in machine production and modeling,

- flexible bands with high strength,

- covers and housings for various devices,

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

| Content [g] | Width [mm] | Outer diameter [mm] | Inner diameter [mm] | Weight empty [g] | Material | Spool color |

|---|---|---|---|---|---|---|

| 250 | 44 | 140 | 52 | 120 | Plastic | Transparent |

| 250 | 44 | 140 | 52 | 80 | Cardboard | - |

| 500 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 750 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 260 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 180 | Cardboard | - |

| 2000 | 100 | 300 | 52 | 600 | Plastic | Black |

| 2000 | 100 | 300 | 52 | 420 | Cardboard | - |

| 4500 | 100 | 350 | 52 | 780 | Plastic | Black |

| 8000 | 167 | 355 | 36 | 1020 | Plastic | Black |

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Do you need help? Do you have any questions?

Ask a question and we'll respond promptly, publishing the most interesting questions and answers for others.

High quality filaments

Wide portfolio consisting of over 80 filaments with a versatile range of properties and applications, divided into three segments: desktop easy-to-use, industrial grade and high performance.

European manufacturing

All filaments from our portfolio are in-house made. We use modern production lines equipped with non-standard solutions to obtain highest quality final product.

technical support

Our qualified support team helps at every stage from material selection to the 3D printing process.